Commercial craft beer equipment is mainly used in hotels, restaurants, barbecue shops, bars, craft beer houses and so on. Craft beer equipment is specially designed to realize the fine brewing of beer, which is different from large-scale beer and home brewed beer equipment. It mainly brews fresh beer of pure malt, which can brew fresh beer of different concentration and taste. Craft beer has the characteristics of diversification, miniaturization, high quality and localization. To bring consumers more diversified flavor and personality choice. The craft beer equipment strictly follows the craft of craft beer, and every detail is deeply refined.

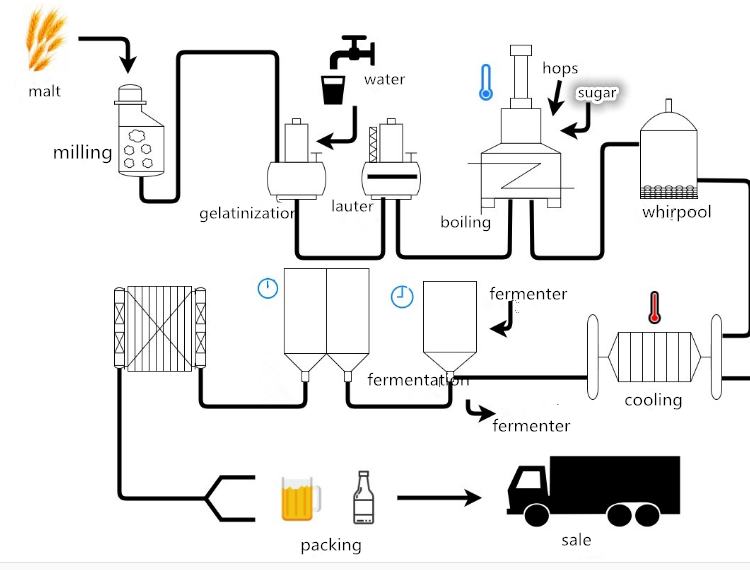

Industrial beer production process flow chart shows that industrial beer has large output, industrial production, low cost, short brewing time, light taste and single taste, which is suitable for big mouth drinking.

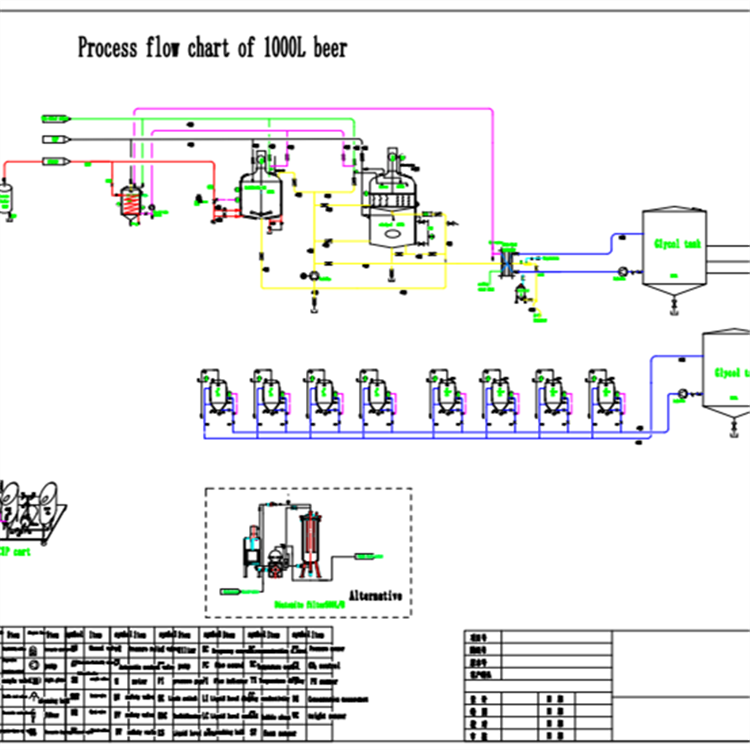

Craft flow chart of craft brewing beer, craft brewing beer pursues variety and individuality of beer flavor, selects high quality raw materials regardless of cost, has long fermentation time, rich flavor and diverse taste.

1. There are many manufacturers, but the form of equipment is single. Because of the low entry threshold of small beer equipment, there are many equipment manufacturers.

2. The equipment performance is backward, which is difficult to meet the needs of high-quality craft beer.

3. The pursuit of low price leads to the lack of key functions. With the aggravation of competition, because there is no technology accumulation, price competition has become the only means for equipment manufacturers to survive. The low price of products directly leads to the sharp decline of equipment quality, which is difficult to meet the needs of brewing beer.

1. Strictly follow the craft beer production process.

2. The equipment is well-made, both inside and outside, the equipment is beautiful in appearance and complete in functions, so as to take care of both.

3. Absorb the scientific research results of current beer, combine the actual production of craft beer, improve the overall performance of craft beer, and provide production conditions for high-quality beer.

4. During the production process of craft beer, automatic control is carried out at key parts to ensure the stability of craft beer production and quality.

1. Malt crushing: Malt needs to be crushed with a malt grinder. Generally, a pair-roller malt grinder is used to break the bark without breaking it and improve the filtering effect.

2. Saccharification process: In the saccharification pot, the malt powder is mixed with water to better dissolve the starch in the malt and convert it to maltose.

3. Filtration process: The solid part of malt becomes lees, which is separated from the liquid part in the filter pot. The liquid formed by filtration is called wort, which is sent to the saccharification pot to boil after filtration.

4. Wort boiling: add hops after the wort is boiled. The boiling time is about 90 minutes. The sweetness of maltose and the bitter aroma of hops are properly mixed to form the unique taste of beer.

5. Cyclone separation: the protein particles coagulated in boiling are separated during the vortex process.

6. Wort cooling: the wort is cooled by a plate heat exchanger, and cooling from the boiling point to 8°C is generally completed within one hour.

7. Fermentation process: Saccharomyces cerevisiae is added to the cooled wort to promote the conversion of maltose into alcohol and carbon dioxide. This fermentation process takes about one week and the fermentation temperature is between 6-20°C.

8. Beer filtration: The yeast and turbid components such as protein produced in the fermentation are filtered out, and the beer becomes cool.

If you want to ask anything just fill in the form below and send us.