How to make Beer and What it Costs

How to make beer by using beer Brewing Equipment:

If your goal is simply to brew a batch of beer and consume it in one sitting with a group of friends, all you need is a brewing bucket, a bubbler, and a siphon hose, or other words,you make beer just want to drink with your family and friend,the aim or brewing beer is not to make money, so that is enougn to make beer at home.

These manufacturer of beer brewing accessories are available at any home brewing store.

When you mix up a batch of beer, it needs to ferment for a week or two, and this bucket makes it quite easy. You simply put your unfermented beer in the bucket, put the bubbler in the little hole on top of the bucket (the bubbler allows gas to escape without contaminating the beer), and let it sit. When you're ready to drink the beer, just open the taps and drink a glass – the hose can make it easier to pour.

Most home brewers tend to want to bottle their beer for long-term storage. If that's the case, you'll need to accumulate roughly fifty empty, clean beer bottles and also a simple bottle filling and capper machine,it can be simple,manually control the machine is ok for most of the people, again available at your local beermaking supply store.and for those bottles and caps in the bottle,it can be used after recycle.This equipment, are all together, will cost or so and are often available in kegs.

When making beer, there are some useful items that are optional:

The large glass bottle or kegs. You can use it for long-term storage of the fermenting beer – it doesn’t last too long in the bucket. Also, I use an auto-siphon (which makes it very easy to siphon beer out of the carboy) and a bottling tip (which makes it very easy to put beer in the bottles). You may also want a hydrometer, which you can use to calculate the alcohol content of the beer you make.

You don’t need these things to make beer, but it does make it easier in some ways. You can leave the beer for a very long time in the carboy and bottling is a much easier process with the auto-siphon and the bottling tip.

The only additional items you’ll need to make your own beer can likely already be found in your kitchen. You’ll need a large pot (one that can hold four gallons of liquid or so), a large spoon to stir it with, a thermometer, and a funnel (if you’re using a carboy). You’ll also need to carefully sanitize any equipment you may use – I use a bleach solution to make sure everything is as clean as possible.

All above of these tips is just for small brewing beer production and those new to brewing,but if you want to make beer in larger scale and make beer and sale beer,maybe the other artical in our website can help u.

We are the professional beer brewing and fermentation system munufacturer,our brewing system from 50L to 5000L,all kinds are optional,to healp you make all kinds of beer,all fresh and delicious craft beer draft beer.

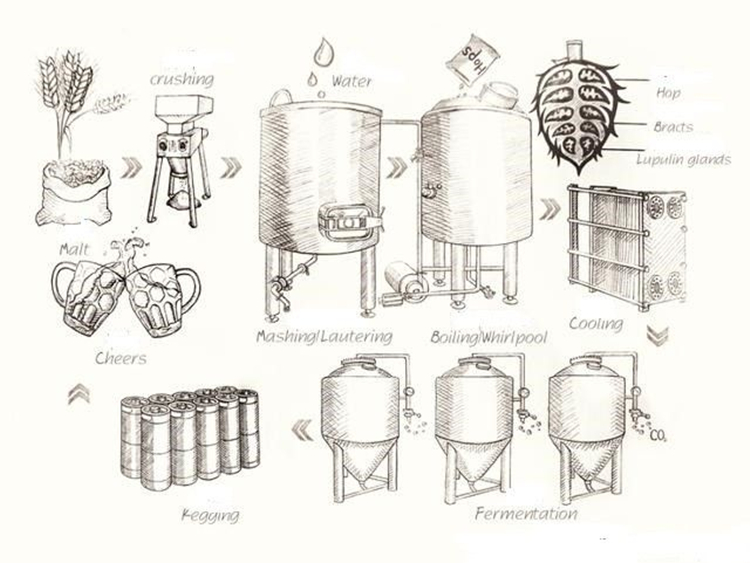

According to our experience in craft beer brewing and production, we have summarized the following brewing process, and hope it will be helpful to you.

How to Make Beer

Below are some processing steps and recipes of beer making,you can see the pictures above,a complete from malt to beer:

6 pounds plain amber malt extract

8 ounces crushed crystal malt (60 L)

4 ounces crushed chocolate malt

4 ounces crushed black patent malt

1 ounce cluster hops (bittering)

1/2 ounce Williamette hops (finishing)

Along with these ingredients, there are a few standard items you'll need for any beer making journey: a grain steeping bag (essentially a teabag for steeping the grains in the water), priming sugar, yeast, and caps.

All of these items are available at a beermaking supply store. I acquired all of the above for roughly .

A big part of the fun of homebrewing is that you can experiment with the recipes as much as you want. For example, my wife and I made an oatmeal stout that went off the recipe quite a bit and it turned out sublimely delicious.

Boil the Water and Steep

Most beer making recipes follow a pretty standard procedure. Just pour two gallons of water into your large pot, heat it to 160 degrees F (80 degrees C) or so, put the grains in the grain bag and tie it off, then drop the grain bag in the water to steep for twenty minutes or so.

Above, I took the picture just after dropping the “tea bag” into the water. The steeping will cause the water to change color, usually to some shade of brown. Here's what it looks like after the steeping.

Adding Malt powder

Once the steeping is finished, you simply bring the pot up to a low boil and add the malt extract (a brown liquid) and the bittering hops. Leave this at a low boil for an hour (stirring it regularly), then five minutes before the end, drop the finishing hops into the mix.

Once it's finished boiling (it's now called “wort”), you'll need to cool it down to 70 degrees – I usually do this by dunking the stock pot into ice water in the sink. I then pour this into the carboy, though you can also do it in the bucket if you don't have a carboy, then I add two to three gallons of filtered water. I then drop in the yeast, stir it a bit, then put the bubbler on top and let it ferment. Here’s a picture of my porter in the carboy at the start of fermentation.

Wait one to two Weeks!

Then you wait. Usually, you'll wait for roughly two weeks. What you're looking for is whether or not there are bubbles coming through the bubbler. Watch it for a minute – if you see no bubbles, wait another three days and you’re ready to finish it up.

then the fresh beer is finishing.

When you're ready to finish it, you simply add the priming sugar to two cups of boiling water, boil the priming sugar/water solution for a few minutes, then add that to the beer. You can then bottle it – if you’re not going to bottle it, you should serve it in the next couple of days.

Bottling is similarly easy. You just thoroughly clean 50 to 60 beer bottles, fill each one carefully, then put a cap on each one with the capping tool (basically, you just put a small disc on top of the bottle, put the capping tool on top, and squeeze). Let the bottles sit for a few weeks and then it’s ready to drink.

If you are comparing the cost of homebrew to the cost of well-made craft beers at the store (which is what most homebrews are comparable to), then homebrewing is actually quite cost effective. In the above example, I used worth of ingredients to make seven six packs of porter, a cost of roughly per six pack. This doesn't include, of course, the cost of the equipment, but this cost is pretty small per six pack if you make many batches. Comparing this to my favorite porter at the local liquor store,homebrewing is substantially cheaper than the craft option.

On the other hand, if you are comparing the cost of making that same porter to the cost of a case of Old Milwaukee (or a similar very inexpensive beer, which can be found for less than per 24 pack), homebrewing isn't cost effective at all and is in fact more expensive than such beer. Admittedly, recipes for mainstream beers are less expensive than recipes for top quality porters – I called a homebrewing supply store and was quoted about for the ingredients I would need for something approximating Old Milwaukee – but the homebrew is still more expensive.

So, the real question is what kind of beer are you replacing with homebrew? If you're replacing great craft beers with your own homemade beer, your costs will in fact go down – and you'll have found a very fun new hobby. However, if you're content just buying some Miller Genuine Draft, homebrewing isn't going to save you much money (if it saves you any at all).

And for beer produced on a small scale, it is difficult to be recognized because it is not on a large scale, and most governments or local food safety and health departments will not grant business licenses. Therefore, even the most delicious beer without business qualification certification and beer safety monitoring and other information is unacceptable to most shops, bars, restaurants and other places.

If you want to do beer distribution and retail or large-scale profit activities, you need to solve it from the source, find a reliable beer distributor or buy a complete set of equipment, and you can apply for permission from the government while seeking supplier opinions certificate.

Commercial beer equipment is at the heart of the modern brewing industry. This article will look at 2000 liter commercial beer equipment, a moderately sized brewing system suitable for small to medium sized bars, restaurants and breweries. We'll learn about its key components, operational processes, and the business considerations associated with them.

More >>

Brewing system: The Restaurant Nano Brewery Equipment brewing system is the heart of any brewery, and a nano brewery is no exception. Restaurant Nano Brewery Equipment typically consists of a mash tun, brew kettle, and fermenter. The size of the brewing system will depend on the amount of beer you plan to brew, but for a restaurant nano brewery, a 1- or 2-barrel system is common.

More >>

Craft brewery equipment is widely used in medium breweries and beer pubs. It can brew pale lager, amber lager, dark lager, ale and etc at proper temperature with different raw material.

More >>

A complete set of 500L beer equipment consists of malt crushing system, saccharification system, fermentation system, steam system, refrigeration system, CIP cleaning system, pipeline system, etc. 500L brewing beer equipment is generally used in commercial, restaurants, bars, barbecue shops and other places.

More >>

100L beer equipment can be used in home brewing and business. Each batch can produce 100L beer, and two batches can be made every day, up to 200L beer. If you are at home, you can produce beer every few days. If it is commercial, first of all, it is necessary to determine how many liters of beer are produced a day. The 100L beer equipment can produce up to three batches a day, but considering the labor intensity, it can produce up to one or two batches a day. The number of fermentation tanks is determined according to the amount of beer produced.

More >>

Small beer equipment is generally divided into two types, one is small household simple equipment, and the other is commercial beer equipment. Small household simple equipment generally refers to 30l-100l, with small floor area, convenient operation and relatively simple technology. Commercial beer equipment generally refers to 300l-2000l beer equipment. Now the popular fine brewing beer equipment in the market is made with this equipment.

More >>

The 100L micro beer equipment belongs to a small beer brewing system. Small space, high degree of automation, simple and easy to operate. The mash process is electric heating, which is generally equipped with two device specifications (mashing+lautering + boiling+whirlpool), with ice water tank, plate heat exchanger, wort oxygenator, wort pump, etc; The fermentation process is automatically controlled by PLC, and 6 fermentation tanks are generally configured according to the standard. It belongs to self entertainment beer brewing equipment.

More >>

If you are planning to build a brewery, you must consider the turnkey beer project. What is the whole turnkey beer production line like? Which manufacturers can do a good job in this beer production line? What problems should we pay attention to? The beginning of a new project certainly requires a lot of preparatory work and a lot of problems. Many times, it is very difficult. This professional problem should be solved by a professional company. We can provide you with the turnkey work of the whole beer project, with more than 60 years of production experience.

More >>

As a popular drink, more and more people like to brew beer. How is beer brewed? According to beer concentration, it is divided into high concentration beer, medium concentration beer and low concentration beer. According to the production mode, it is divided into: fresh beer, pure draft beer and cooked beer. No matter what kind of beer, the beer brewing system is divided into: malt crushing system, saccharification system, fermentation system, CIP cleaning system, refrigeration system, control system, filling system and water treatment system.

More >>

As one of the oldest beverages in the world, beer has a history of 4000-5000 years. It uses malt as the main raw material, adds hops, and is brewed by yeast. Craft beer is actually an innovation movement in the beer industry. Behind it is the rise of the young consumers born in the 80s and 90s. They have higher requirements for consumer experience, personalization and diversification.

More >>

For beer equipment, each customer has different requirements. We have talked about what equipment beer equipment needs, how to choose beer equipment, and what is the most suitable scheme? According to the different needs of each customer, today we will talk about the additional configuration of beer equipment, so that we can use it better and more conveniently to brew higher quality beer.

More >>

As the core of the whole beer equipment, saccharification system is the key to brewing beer, so how to choose the saccharification system suitable for you? As we all know, the saccharification system is divided into four steps: saccharification - Filtration - boiling - spin sedimentation. In order to achieve the desired effect in each step and save cost, the combination of saccharification system is very key.

More >>